MONO Equipment’s NEW Automatic Injector has been designed to consistently and accurately fill doughnuts and pastries with a wide range of fillings.

Featuring a NEW 65k OLED colour screen the Automatic Injector can store up to 85 Pictorial and up to 99 Numerical programmes. The Auto Injector comes pre-loaded with a range of colourful icons featuring some of the most popular fillings available on the market; other pictorial icons can also be added to extended to suit your specific needs if required. If you prefer to use the Numerical or Manual Modes, however, switching to your chosen mode is easily done at the touch of a button.

The new controller also incorporates Variable Speed and Suck Back settings which can be set for each programme to ensure exceptional accuracy. A new Continuous Mode function allows the Auto Injector to produce a continuous stream of filling until stopped by the user.

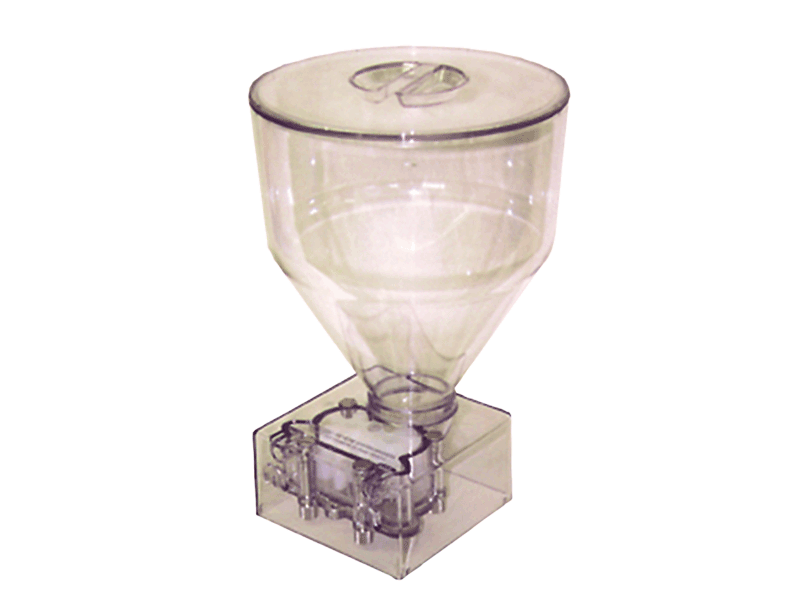

The Automatic Injector features two injector needles which make clean and accurate insertions into a wide range of products – without mess or waste. Fillings can be quickly and easily altered by simply changing the hoppers.

All hoppers are crafted in easy-to-clean reinforced plastic and have also been designed for easy viewing of the filling level inside.

A Foot Pedal is also available which means the Auto Injector can be activated using a convenient foot switch instead of the Activator Tray; ideal if you are injecting large volumes of product.

A series of tool accessories will also be available soon to extend the use of the Auto Injector even further.